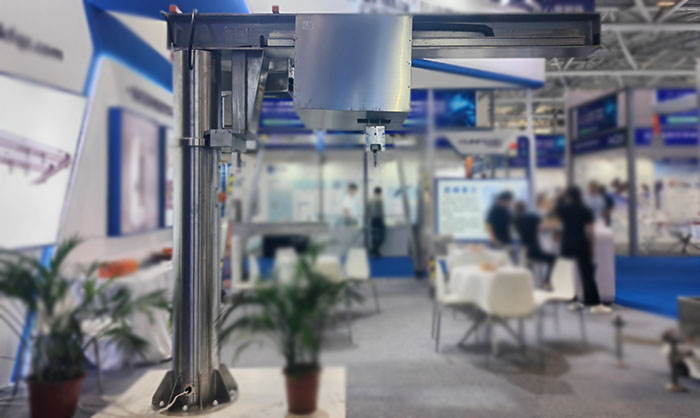

“A jib crane, also known as a slewing arm crane, is a small to medium-sized arm-type lifting equipment consisting of a column, a slewing arm and an electric hoist. It can rotate 360° or 180° and is suitable for short-distance, high-frequency and intensive lifting operations. It has the characteristics of small footprint, flexible operation, high efficiency and energy saving, and is widely used in factories, mines, workshops, warehouses and other scenarios.”

A jib crane is a light-to-medium-sized lifting device. Its core feature is a "cantilever beam" structure that rotates around a fixed fulcrum (or column). This allows for lifting, moving, and rotating cargo within a specific radius. It is widely used in workshops, warehouses, logistics stations, and other locations to meet precise lifting needs in localized areas.

The basic structure consists of three parts: the cantilever beam (usually made of steel, either telescopic or fixed in length), which bears the load; the column/fixed base (fixed column types require floor anchoring, while wall-mounted types require attachment), which provides stable support; and the lifting and rotating mechanism (equipped with an electric hoist or manual winch, capable of 360° or 180° rotation) that facilitates cargo movement.

Compared to traditional lifting equipment, jib cranes offer three key advantages:

1. High space utilization: The column occupies a small footprint, and the cantilever can rotate to cover a circular or sector-shaped operating area, making it particularly suitable for space-constrained locations such as factories and warehouses.

2. Flexible and convenient operation: Electric hoists support wireless control and precise positioning, enabling quick response to production needs and reducing manual handling time.

3. Economical and durable: Utilizing high-strength steel and a modular design, they offer low maintenance costs and a service life of 8-10 years, offering excellent overall cost-effectiveness.

Jib cranes, with their efficiency, flexibility, and safety, are an ideal choice for material handling in small and medium-sized sites. Whether in machining, warehousing and logistics, automotive repair, or food processing, jib cranes can be customized to precisely meet your needs, helping businesses improve production efficiency and reduce operating costs.