Call Us

+86-15201969650

Get Location

No.5358 Huyi Road, Jiading District, Shanghai, China

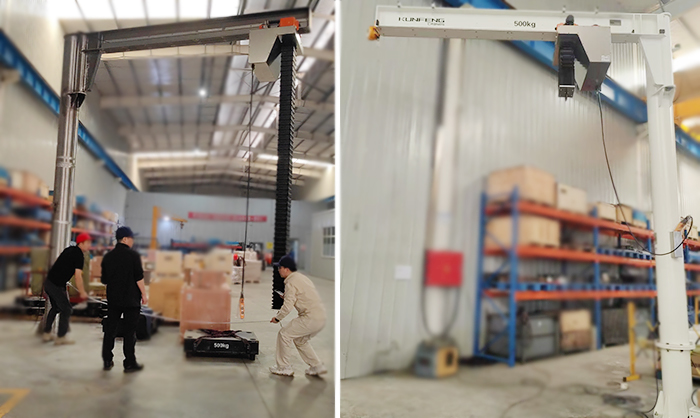

Carbon steel industrial cantilever crane is a small and medium-sized lifting equipment that combines high load-bearing capacity and flexible operation. It is widely used in manufacturing, logistics warehousing, automobile and shipbuilding and other fields. The following is a comprehensive introduction to its core characteristics and advantages:

Definition and structure

Carbon steel industrial jib crane consists of a column, a slewing arm, an electric hoist, a rotating mechanism and an electrical control system.

The column is fixed to the concrete foundation by anchor bolts to provide stable support; the slewing arm is made of carbon steel and driven by a cycloidal pinwheel reduction device, which can rotate freely in the horizontal plane.

The electric hoist moves along the I-beam track of the slewing arm to realize the lifting and handling of goods. The electrical control system serves as the "brain" to ensure accurate and safe operation.

The core advantages of steel industrial cantilever crane

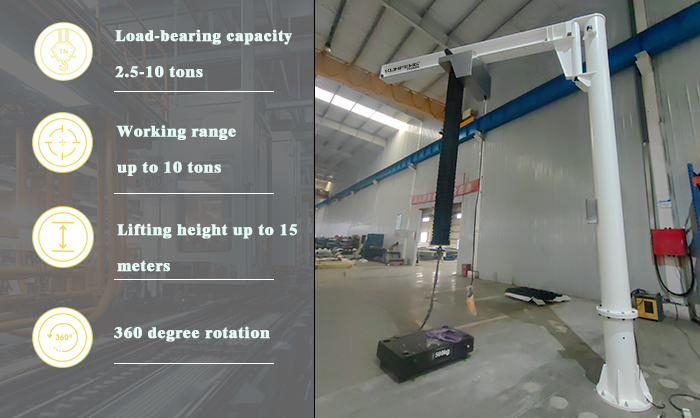

Carbon steel is the preferred material for cantilever structure due to its high strength and rigidity. It can carry a load range of 150kg to 5000kg, covering light to heavy needs.

By optimizing the crystal structure through heat treatment or enhancing the surface corrosion resistance through shot peening, the carbon steel cantilever takes into account durability and economy, and is especially suitable for industrial environments with frequent operations. The hollow steel design of the industrial cantilever crane further reduces its own weight and improves the span and load efficiency.

Performance characteristics

Flexible and efficient: The industrial cantilever crane has a slewing radius of 360 degrees and can be accurately positioned in three-dimensional space, which is suitable for narrow environments such as workshops and warehouses;

Easy to operate: The new generation of models is equipped with a wireless remote control system as standard, with a control distance of up to 100 meters, and supports single-person remote control;

Safe and stable: The mechanical balance principle is integrated into the structural design, and the stability is maintained in both empty and heavy load states;

Energy-saving and economical: Lightweight design reduces energy consumption, modular structure reduces maintenance costs, and the service life is up to more than 10 years.

Industrial jib cranes have outstanding performance in automobile assembly lines, metal processing workshops, port terminals and other fields, and are especially suitable for intensive material transportation, such as spare parts turnover, mold installation and other scenarios. We can customize the design of industrial cantilever crane solutions according to your needs. Please contact us immediately!