“Cleanroom cranes are specialized lifting and handling systems designed for use in cleanroom environments, where contamination control is critical.”

In the semiconductor wafer foundry industry, maintaining a contamination-free environment is crucial for ensuring the integrity and performance of the wafers produced. Cleanroom cranes play an indispensable role in this process, providing efficient and contamination-free handling of materials and equipment.

What Are Cleanroom Cranes?

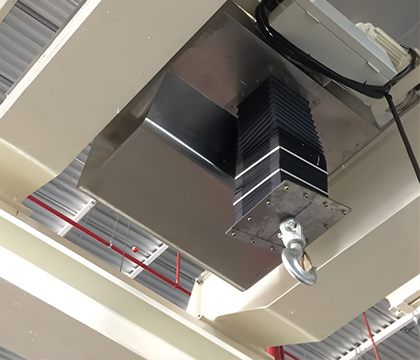

Cleanroom cranes are specialized lifting and handling systems designed for use in cleanroom environments, where contamination control is critical. These cranes are constructed with materials and technologies that minimize particle generation and ensure compliance with stringent cleanroom standards.

Cleanroom cranes are designed based on the specific requirements of the semiconductor industry. They are constructed to meet ISO cleanroom classifications, often targeting Class 100 or Class 10000 cleanroom standards.

Modular Design: Many cleanroom cranes feature a modular design, allowing for easy customization and integration into existing cleanroom environments.

Anti-static Materials: To prevent electrostatic discharge (ESD), which can damage sensitive electronic components, cleanroom cranes are often designed with stainless steel and anti static coatings to prevent static.

Why Are Cleanroom Cranes Essential in Semiconductor Wafer Foundries?

• Contamination Control

Semiconductor manufacturing requires an ultra-clean environment to prevent defects in wafers. Even microscopic particles can cause significant defects, leading to reduced yield and compromised performance. Cleanroom cranes help maintain this sterile environment by ensuring that the handling of wafers and equipment does not introduce contaminants.

• Precision and Reliability

Cleanroom cranes are engineered for precision, allowing for the delicate and accurate handling of sensitive materials. This precision is vital in semiconductor wafer foundries, where the slightest misalignment can lead to costly errors.

• Efficiency and Safety

Automated cleanroom cranes improve operational efficiency by speeding up the handling and transfer processes. They also enhance safety by reducing the need for manual handling, which can introduce human error and contamination.

Cleanroom cranes are a vital component in the semiconductor wafer foundry industry, ensuring that the delicate process of wafer production is conducted in a contamination-free environment. Their precision, reliability, and efficiency make them indispensable tools in maintaining the high standards required for semiconductor manufacturing.

If you are looking to enhance your semiconductor wafer foundry operations with state-of-the-art cleanroom cranes, contact us today to learn more about our advanced solutions tailored to meet your specific needs.