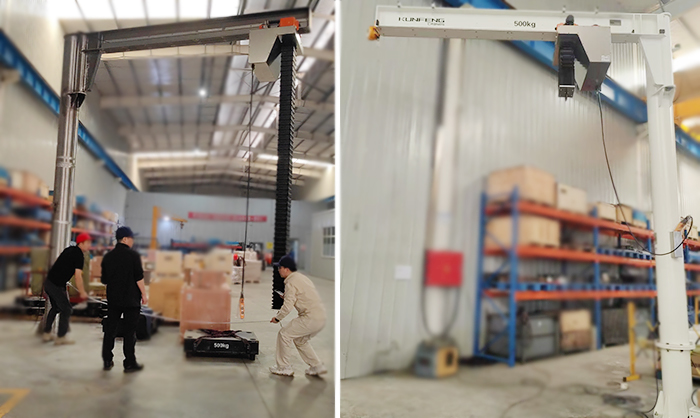

“A cantilever crane is usually composed of a column, a cantilever and a drive device. It can complete material handling by rotating and lifting the cantilever. It is widely used in factories, warehouses, docks and other places. It has the characteristics of flexible operation and small space occupation.”

As a small and medium-sized lifting equipment, the cantilever crane plays a key role in many industrial fields with its unique structure, flexible operation, high efficiency and energy saving. Its three-dimensional spatial operation capability is particularly suitable for short-distance, high-frequency intensive lifting scenes, which significantly improves the operation efficiency. The following are its core application areas:

1.Industrial manufacturing and assembly

① Workshop handling: In automobile and machinery manufacturing workshops, cantilever cranes are used to lift heavy parts (0.5-10 tons) such as engines and gearboxes, and cooperate with the assembly line for precise positioning to achieve efficient assembly.

② Machine tool loading and unloading: The 360° rotation function can complete machine tool material handling and mold replacement in a limited space, reducing the intensity of manual handling.

2.Logistics warehousing and terminal operations

① Warehouse cargo transfer: The column design saves space and is suitable for stereoscopic warehouses. The vertical lifting and horizontal movement are seamlessly connected, and long goods such as steel and pipes are efficiently stacked.

② Port loading and unloading: Quickly lift containers or bulk cargo at the dock to realize the transfer of cargo ships and shores.

3. Construction and maintenance

① Building materials lifting: outdoor dust-proof cantilever cranes (arm length up to 6 meters) transport steel bars and prefabricated components, with a wide coverage range, accelerating the construction of high-rise buildings.

② Equipment maintenance: used for high-risk operations such as power plant motor disassembly and ship engine maintenance, precise control to ensure safety.

4. Special scene expansion

① Garbage disposal: transport large pieces of garbage materials, assist in classification and cleaning.

② Aerospace: install and repair aircraft precision parts to support high-precision operation requirements.

Selection reference: According to the scene requirements, you can choose fixed column type (125-5000kg), mobile type (emergency lifting), wall type (saving ground space) or curved arm type (avoiding obstacles) and other types.

With modular design and intelligent upgrades (such as anti-sway control and automatic positioning), cantilever cranes are becoming the core equipment for modern industrial automation upgrades, and continue to promote productivity innovation in various fields. Welcome to contact us to get a customized cantilever crane solution!