“Warehouse cranes are divided into different types, including bridge cranes, cantilever cranes, gantry cranes, etc., which are suitable for different types of storage. Contact Converson manufacturers to obtain customized solutions, and regularly maintain the equipment to extend its service life.”

Cranes are divided into many types, such as bridge cranes, cantilever cranes, and gantry cranes. Different types of cranes are suitable for different storage scenarios, and multiple factors such as load requirements, space layout, and frequency of use need to be considered comprehensively.

Detailed introduction to different types of warehouse cranes:

1. Bridge crane

KBK bridge cranes run on fixed tracks and are available in single and double beams. The beam is a horizontal beam that runs through the length of the crane, enabling the lifting mechanism to move horizontally, making it an ideal choice for warehouses that require horizontal transportation. They can be manual, electric, or pneumatic, depending on your needs.

2. Cantilever crane

Cantilever cranes are designed for lifting operations that require more functionality. This type of crane is equipped with a vertical mast, boom, and hoist for lifting objects. They can move objects vertically and horizontally and provide a 360-degree rotation range. Cantilever cranes can be freestanding, floor-standing, or wall-mounted, and take up less space.

Cantilever cranes are ideal for small workspaces and large warehouses, and can be combined with bridge cranes for maximum efficiency. Cantilever cranes come in a variety of sizes and are available in three types: manual, pneumatic, and electric.

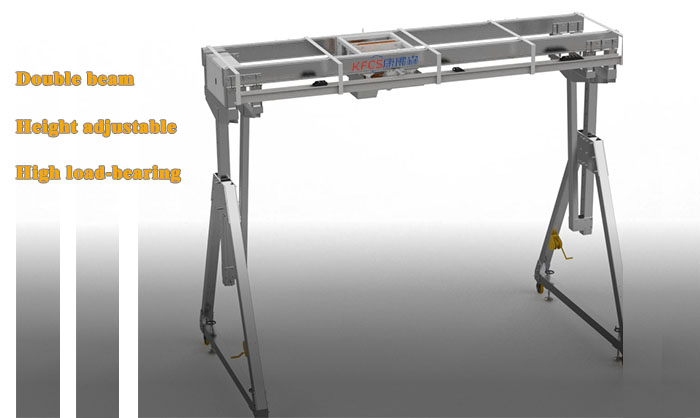

3. Gantry crane

A gantry crane is a crane mounted on a gantry or portable frame, usually equipped with wheels.

This type of crane has a wide range of uses and can be used for both small operations such as auto repair shops and large operations.

KBK bridge cranes are the preferred solution for warehouses with compact space and frequent cargo turnover. It has a simple structure and flexible operation. It usually covers a span range of 7.5 meters to 37.5 meters and can lift up to 20 tons, which can meet the daily lifting needs of most warehouses.

If the warehouse has a low floor height or needs to move goods frequently, a cantilever crane is also an ideal choice. It is suitable for handling light loads (such as small parts) and is easy to install. It is recommended that you contact the Kangfusen manufacturer to obtain a customized solution and regularly maintain the equipment to extend its service life. Through scientific selection, cost reduction, efficiency improvement and safety upgrade of warehousing logistics can be achieved. Please contact us immediately.